Log In

Log InHaloJrMax

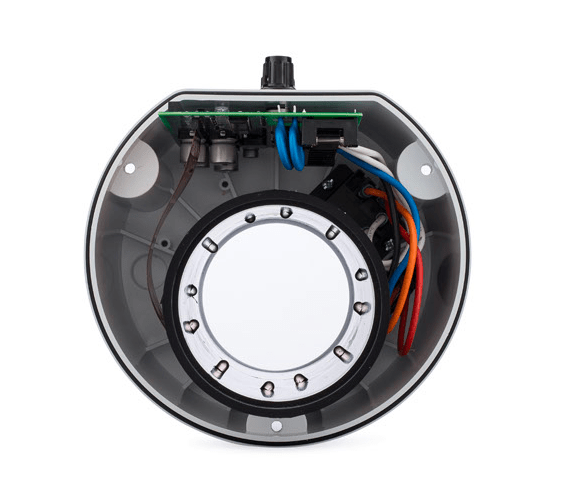

The Halo Feed System Control is the solution to feed delivery control needs. Halo uses an infrared sensor and fully featured electronics to manage a livestock feed system. The sealed plastic enclosure resists corrosion and the harsh barn environment.

Turn Dial Controls

Ready. Set. Go.

Max Run Timer stops motor when max run time is surpassed. This feature prevents unwanted feed spills and excess wear on the motor when feed bins run empty.

Delay Start Timer delays starting the feed motor until the specified delay time has surpassed. This feature prevents short-cycling of the motor increasing the motor life-span.

Infrared Sensing

Proven time and time again.

Six pairs of high power infrared emitters and receivers blast through all types of feed. This proven technology will work whether you are feeding a fine powder, whole corn and anything in-between. Unlike a proxy switch, changes in temperature, moisture, humidity or feed density will not impact the HaloJrMax infrared sensors.

Installation

Simple to install. Simple to use.

You will be amazed how quickly you can install your HaloJrMax feed controller into a new or existing feed system. Simply connect the HalojrMax below the drop boot at the end of the feed line and install a drop tube below the Halo.

Wiring

Get up and running, quicker.

The HaloJrMax operates on voltages between 85-300 VAC. This means no toggle switches or jumper wires to get right. It also means there are only four wires to connect for installation. Wire the HaloJrMax direct to the feed motor and power source or through a control box to integrate backup safety switches.

Alarm Contact

Notifications to keep you running.

Alarm output is standard on all HaloJrMax units. A prewired alarm output is optional. Just ask your distributor for the HaloJrMax Alarm. The alarm will notify you of out of feed events caused by a Max Run or continuous run time.

Specifications

It’s what’s on the inside that matters.

- Universal Power Supply: 85-300 VAC

- Motor Contact: 20 Amp dry contact / 1.5 HP Max

- Alarm Contact: 1 Amp dry contact

- Weight: 3.5 lbs

- Dimensions: 9.7" H x 7.3" W x 6.7" D

- Inlet: 3.5" ID x 3.5" ID x 4" OD

- Warranty: 2 Years

- Models: HaloJrMax, HaloJrMaxA (Alarm)